Optimised material handling technology

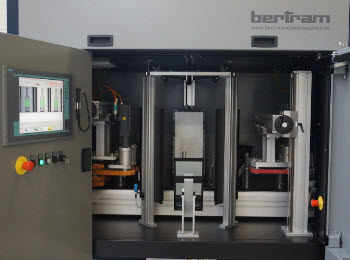

Our Line control system has been designed specifically for the “cold end” of the container glass industry. It includes electrical and control technology engineering, switch gear manufacturing, installation and on-site start-up. Bertram Elektrotechnik has become an innovation pioneer in control systems for glass container transport, due to its extensive experience and knowledge of the material and the requirements of the industry.

Adjustments during a job-change represent unproductive times, which need to be minimised. For the material flow in glass plants precise adjustments need to be made to the belt speed for each product along side the mechanical adjustments. As our Line control system automatically calculates the product specific speed, it contributes to an increase of productivity in the container glass production process.

|

Orientator |

|

|

|

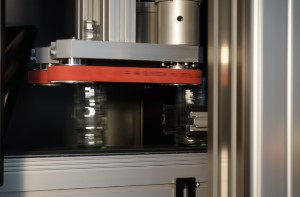

ProcedureThe completely automated bottle Orientator combines the three process steps: separation; recognising the current position; and positioning into the desired position in a compact combination from calculation based image processing and motion application optimised Simatic T-CPU. The space saving structure makes it possible for the machine to be easily integrated even into existing conveyor systems. The products enter the machine on a conveyor belt. It is firstly guaranteed by the spacers that a minimum gap is maintained between the products. The guides then bring the speed of the containers back up to match the conveyor belt speed ensure they remain stable. The Simatic T-CPU records the products with a photo cell and triggers the product orientation evaluation at a given point using the BV-system. The industrial image processing system recognises the position of the container in a three dimensional model using three cameras and predefined characteristics, and from this it generates the necessary correction angle, that is used by the T-CPU, to parameterise and trigger the turning process in the Orientator. The respective orientation direction depends on the shortest distance to the destination angle, according to the industrial image processor’s recording. To ensure that the products remain stable at this point as well, the turn station works at the same speed as the aforementioned conveyor belt. As a Siemens partner, Bertram holds a high level of drive and automation technology as well as SPS-programming know-how along with their expertise in industrial image processing. |

|

| More Information | |

|

Separator |

|

|

|

Bertram’s bottle separator consists of a powerful industrial image processor, that is controlled by a pre-programmed, ready to use IPC-control system and a servomotor driven Allocator. Individual adjustments to the respective applications can be made directly on the module, either through an integrated touch screen, a USB connection with an external keyboard, or, the most convenient, remotely from your PC. We use forward-looking technology based on real-time ethernet, in the form of Profinet-communication at the input/ output level. |

|

| More Information | |

|

Allocator |

|

|

|

The function principle is, in essence, based on a rotary, eccentric allocation wheel, that can transport bottles, as an example, independent of their load and with a smooth movement, to a parallel conveyor track. An industrial image processor, such as our separator, determines, according to a predefined analysis framework, which container is to be transferred. This can be dependent on quality characteristics such as label position, bottle colour, or closure position. In its Allocator, Bertram is deliberately passing on the any of the usual pneumatic solutions. As the rotary servo-method works considerably faster, wear-free and due to the fact that it goes without expensive compressed air, far more energy efficient. |

|

| More Information | |

|

Complete line control systems |

|

Adjustments during a job-change represent unproductive times, which need to be minimised. For the material flow in glass plants precise adjustments need to be made to the belt speed for each product along side the mechanical adjustments. As our Line control system automatically calculates the product specific speed, it contributes to an increase of productivity in the container glass production process |

|

| More Information |

Bertram combines precise and highly dynamic servo drive technology with quick industrial image processing. Using this, we have developed a machine that orientates bottles and jars with extreme accuracy. The in-line ‘Orientator with a recognition system’ can turn up to 500 containers per minute into a desired position. The belt Orientator (or belt orienter), which holds the Lower Saxony Handwork Innovation prize, efficiently and smoothly turns containers to the desired position for the following production step. Palletising, filling, capping or labelling machines can then work considerably faster. In summary, productivity increases, if nothing else, through the skillful exploitation of industrial image processing.

Bertram combines precise and highly dynamic servo drive technology with quick industrial image processing. Using this, we have developed a machine that orientates bottles and jars with extreme accuracy. The in-line ‘Orientator with a recognition system’ can turn up to 500 containers per minute into a desired position. The belt Orientator (or belt orienter), which holds the Lower Saxony Handwork Innovation prize, efficiently and smoothly turns containers to the desired position for the following production step. Palletising, filling, capping or labelling machines can then work considerably faster. In summary, productivity increases, if nothing else, through the skillful exploitation of industrial image processing. The Separator allows bottles and/or jars to be distributed between up to four tracks without changing the production speed. With its fast industrial image processing in combination with the corresponding SPS-programming, Bertram’s system works so flexibly that it can handle all standard tasks. Resulting, in essence, from the shape and number of bottles and/ or jars, and their allocation to the correct tracks.

The Separator allows bottles and/or jars to be distributed between up to four tracks without changing the production speed. With its fast industrial image processing in combination with the corresponding SPS-programming, Bertram’s system works so flexibly that it can handle all standard tasks. Resulting, in essence, from the shape and number of bottles and/ or jars, and their allocation to the correct tracks. Allocators are integral parts of inline-sorting, above all, in bottling plants and the food and drink industry. Due to the high production speed, modern systems work with powerful control systems, highly dynamic drive technology and precise industrial image processing. We have developed our own Allocator based on our comprehensive know-how of the container glass manufacturing process. This combines image processing, SPS and servo-motor drive technology into a compact and easy to integrate unit.

Allocators are integral parts of inline-sorting, above all, in bottling plants and the food and drink industry. Due to the high production speed, modern systems work with powerful control systems, highly dynamic drive technology and precise industrial image processing. We have developed our own Allocator based on our comprehensive know-how of the container glass manufacturing process. This combines image processing, SPS and servo-motor drive technology into a compact and easy to integrate unit. Our Line control system has been designed specifically for the “cold end” of the container glass industry. It includes electrical and control technology engineering, switch gear manufacturing, installation and on-site start-up. Bertram Elektrotechnik has become an innovation pioneer in control systems for glass container transport, due to its extensive experience and knowledge of the material and the requirements of the industry.

Our Line control system has been designed specifically for the “cold end” of the container glass industry. It includes electrical and control technology engineering, switch gear manufacturing, installation and on-site start-up. Bertram Elektrotechnik has become an innovation pioneer in control systems for glass container transport, due to its extensive experience and knowledge of the material and the requirements of the industry.